Favorite Tips About What Is An Example Of A BOM List

Unraveling the Mystery

1. Breaking Down the Basics of a BOM

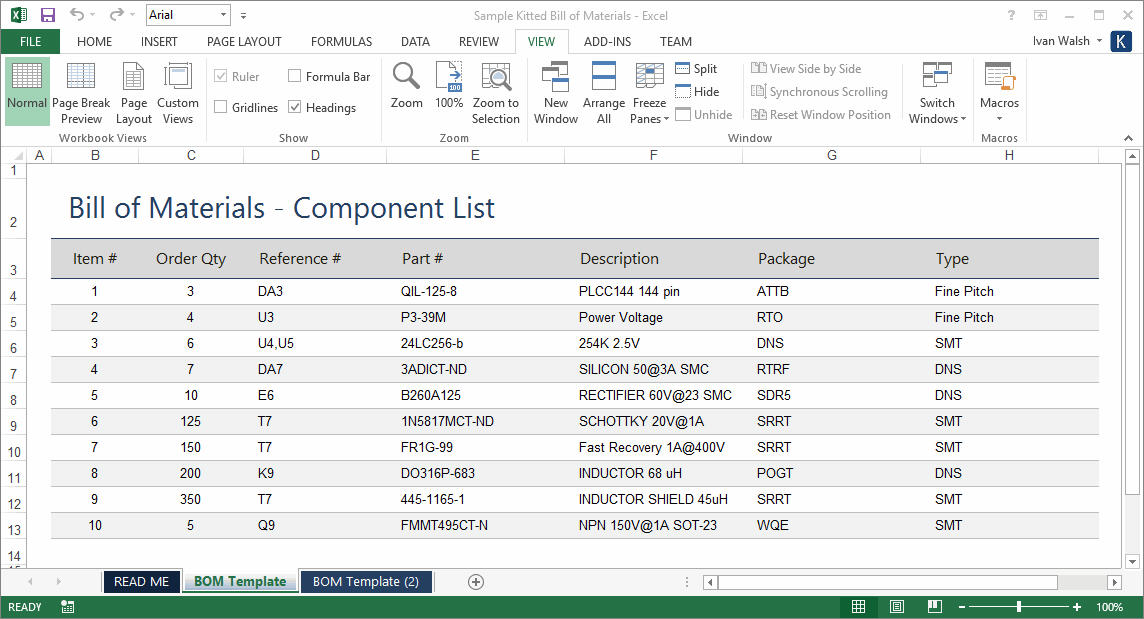

Okay, so you've probably heard the term "BOM list" thrown around, especially if you're involved in manufacturing or engineering. But what does it actually mean? Think of it as a recipe, but instead of delicious cookies, you're creating, say, a super-cool gadget. A BOM, short for Bill of Materials, is essentially a comprehensive, structured list of all the raw materials, components, assemblies, and quantities needed to manufacture a product.

Imagine you're building a bicycle. Your BOM list would include everything from the frame and wheels to the tiny nuts and bolts that hold it all together. Its not just about what you need, but how much of each thing. This meticulous detail ensures that nothing is overlooked when you're ready to start production. Without a well-organized BOM, you might find yourself missing crucial parts halfway through the process, which can lead to delays, increased costs, and a whole lot of frustration. Nobody wants that!

BOMs aren't just for physical products, either. They can also be used in software development to track the various software components and libraries needed for a particular application. The key is that it's a complete inventory of everything required to build something, whether it's tangible or virtual. Think of it as the ultimate shopping list for your project — one that ensures you don't end up with a half-built bike or a buggy app!

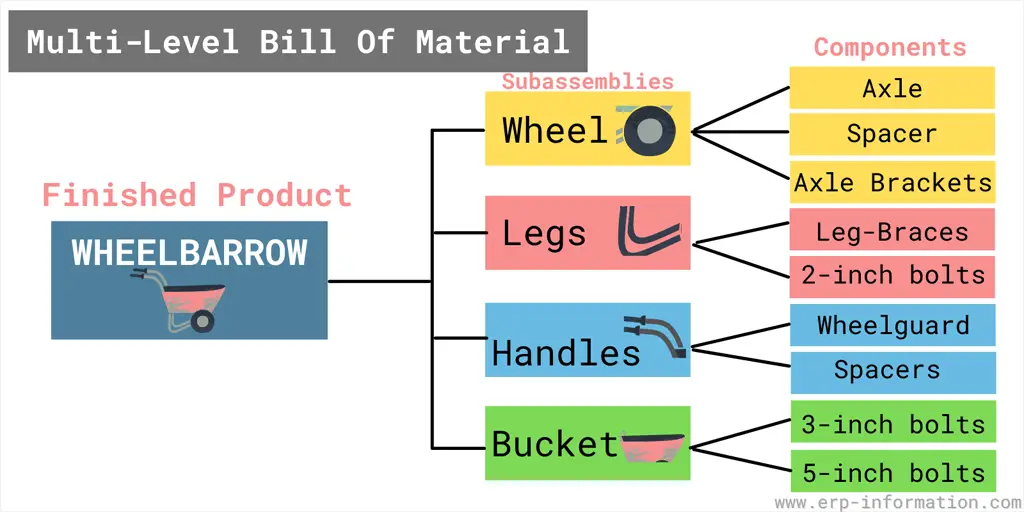

Now, BOMs can vary in complexity depending on the product. A simple product might only need a single-level BOM, listing all the direct components. A more complex product, however, could require a multi-level BOM, also known as an indented BOM, which breaks down assemblies into sub-assemblies and their respective components. We'll delve a bit deeper into that later, but for now, just remember: a BOM is your indispensable guide to building anything, big or small.

How To Create An Accurate Bill Of Materials (BOM) List Avontus® Software

An Illustrative Example

2. Deconstructing a Modern Marvel

Let's make things a bit more concrete. Instead of just talking about abstract concepts, let's dissect a common, everyday item: a smartphone. Creating a BOM for a smartphone highlights just how intricate these lists can become. The sheer number of individual components needed to build one of these pocket-sized powerhouses is staggering.

The BOM would include obvious items like the display screen, the battery, the camera modules (front and back), and the processor (the brains of the operation!). But it doesnt stop there. It would also list less conspicuous items, such as the various circuit boards, resistors, capacitors, and other tiny electronic components. Think about the SIM card tray, the volume buttons, the charging port, and even the tiny screws that hold everything together. Each of these needs to be accounted for in the BOM.

Furthermore, the smartphone's BOM would specify the precise grade and specifications of each component. For example, the display screen might be listed with its resolution, size, and manufacturer. The battery would be defined by its capacity, voltage, and chemistry. This level of detail ensures that the correct parts are used and that the final product meets the required performance standards. A slight variation in component quality can drastically impact the phones overall functionality and lifespan.

And remember, this is just a simplified overview! A real-world smartphone BOM would likely be hundreds of lines long, detailing every single component and sub-assembly with excruciating precision. It's a testament to the complexity of modern manufacturing and the importance of having a well-managed and accurate BOM. It's not just about listing parts; it's about specifying exactly what parts are needed, how many, and where they go in the manufacturing process. It's the backbone of efficient production.

![FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD] FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD]](https://www.dailylifedocs.com/wp-content/uploads/2022/03/BOM-Template-2578902-1024x720.jpg)

Different Flavors

3. Picking the Right BOM for the Job

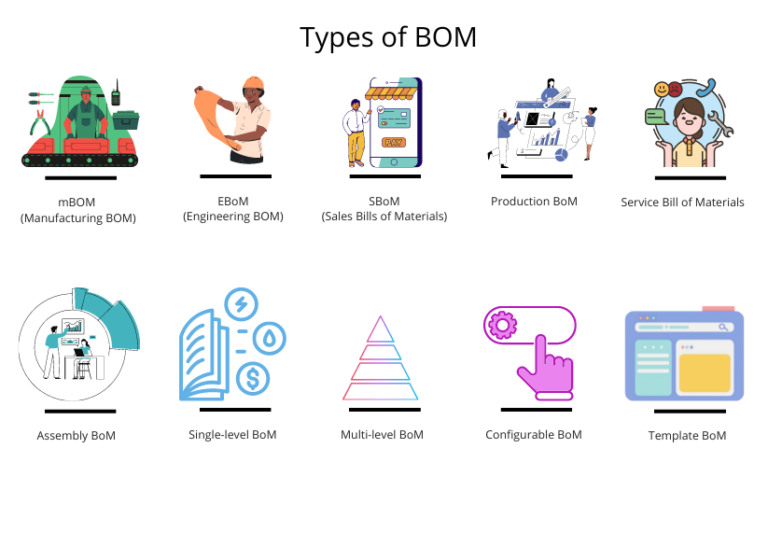

Not all BOMs are created equal. Just as there are different types of recipes for different dishes, there are different types of BOMs tailored for specific purposes. Understanding these different types can help you choose the right one for your specific needs and optimize your manufacturing process.

First, there's the engineering BOM (EBOM). This is the BOM that's created during the design and engineering phase of a product. It's typically used by engineers to define the product's structure and components, focusing on the technical aspects. The EBOM might include components that are not directly related to manufacturing, such as testing equipment or software libraries. This helps engineers ensure that all design requirements are met, even if some components are only used during the development process.

Next, we have the manufacturing BOM (MBOM). As the name suggests, this BOM is used specifically for manufacturing the product. It includes all the components, sub-assemblies, and materials required for production. The MBOM is often derived from the EBOM, but it's tailored for the manufacturing process, including details like packaging materials, manufacturing instructions, and routing information. It's the go-to guide for the production team, ensuring they have everything they need to build the product efficiently.

Finally, there's the sales BOM (SBOM), which is used for sales and order management. This BOM lists the components that are included in a finished product when it's sold to a customer. It might include options or accessories that the customer can choose from. For example, if you're selling a laptop, the SBOM might list the different operating systems, memory configurations, or warranty options that are available. The SBOM helps sales teams configure orders accurately and ensure that customers receive exactly what they've ordered.

Choosing the right type of BOM is critical for streamlining your operations. Using an EBOM for manufacturing can lead to confusion and inefficiencies, while using an SBOM for engineering can result in design flaws. By understanding the different types of BOMs and their intended uses, you can optimize your processes and improve your overall efficiency.

What Is The Bill Of Materials (BOM)? A Comprehensive Guide

Why Bother? The Benefits of a Well-Managed BOM

4. Reaping the Rewards of Organization

You might be thinking, "Okay, BOMs sound important, but are they really worth the effort?" The answer, unequivocally, is yes! A well-managed BOM can bring a host of benefits to your organization, from improved efficiency and reduced costs to enhanced product quality and better inventory control.

One of the most significant advantages is improved efficiency. With a comprehensive and accurate BOM, everyone involved in the product lifecycle — from engineers to manufacturers to salespeople — has a clear understanding of what's needed and how it fits together. This eliminates confusion, reduces errors, and streamlines the entire process. Imagine trying to build a house without blueprints; a BOM is the blueprint for your product.

Another key benefit is reduced costs. By accurately tracking materials and components, you can minimize waste, optimize inventory levels, and negotiate better prices with suppliers. A well-managed BOM helps you avoid overstocking or running out of critical parts, both of which can be costly. It also allows you to identify opportunities for cost savings, such as substituting cheaper components or streamlining the manufacturing process.

Furthermore, a BOM contributes to enhanced product quality. By ensuring that the correct parts are used and that the product is assembled according to specifications, you can reduce the risk of defects and improve the overall reliability of your products. A clear BOM also facilitates troubleshooting and debugging, making it easier to identify and resolve any issues that arise during the manufacturing process. Ultimately, a well-managed BOM translates to higher-quality products and more satisfied customers.

Finally, a BOM provides better inventory control. By accurately tracking materials and components, you can optimize your inventory levels, reduce waste, and avoid stockouts. A BOM also helps you manage changes to your product more effectively. If you need to substitute a component or update the design, you can easily identify all the affected parts and update your inventory accordingly. This ensures that you always have the right parts on hand and that your production process runs smoothly.

![FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD] FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD]](https://www.dailylifedocs.com/wp-content/uploads/2022/03/BOM-Template-2578911.jpg)

FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD]

BOM Software and Tools

5. Leveraging Technology for BOM Management

Creating and managing BOMs manually can be a daunting task, especially for complex products with hundreds or thousands of components. Fortunately, there are a variety of software and tools available to help streamline the process and make your life easier. These tools can automate many of the tasks associated with BOM management, from creating and editing BOMs to tracking inventory and managing changes.

One popular type of BOM software is Product Lifecycle Management (PLM) software. PLM systems are comprehensive platforms that manage all aspects of a product's lifecycle, from design and engineering to manufacturing and sales. They typically include robust BOM management capabilities, allowing you to create, edit, and manage BOMs with ease. PLM systems also provide features for change management, configuration management, and collaboration, making it easier for teams to work together on product development.

Another option is Enterprise Resource Planning (ERP) software. ERP systems are designed to manage all aspects of a business, including finance, accounting, supply chain management, and manufacturing. Many ERP systems include BOM management modules that integrate seamlessly with other business functions. This allows you to track inventory levels, manage orders, and plan production based on your BOM data. ERP systems can be particularly useful for businesses that need to manage large and complex product portfolios.

In addition to PLM and ERP systems, there are also a number of standalone BOM management tools available. These tools are typically more focused and less expensive than PLM or ERP systems, making them a good option for smaller businesses or teams with specific BOM management needs. Standalone BOM tools often provide features for creating, editing, and managing BOMs, as well as reporting and analytics. Choosing the right BOM software or tool depends on your specific needs and budget. Consider factors such as the complexity of your products, the size of your team, and your integration requirements when making your decision.